Chinese precision injection molding manufacturers offer significant cost advantages, with lower wage rates and material costs that can be halved compared to Western countries. They boast high in-house production capacities, capable of fulfilling large orders efficiently. China’s well-developed plastic supply chain ensures timely delivery despite geographical distances. Additionally, Chinese precision injection molding manufacturers are technically skilled, consistently delivering high-quality work. Over the past two decades, China’s injection mold technology has advanced significantly, positioning the country as a global leader in mold manufacturing, especially with the growth of the automotive and new energy vehicle industries.

Location: Dongguan, Guangdong

Founded: 2004

Core Services: Plastic injection molds and spare parts (i.e., cylinder parts, ejector pins, and any customized parts)

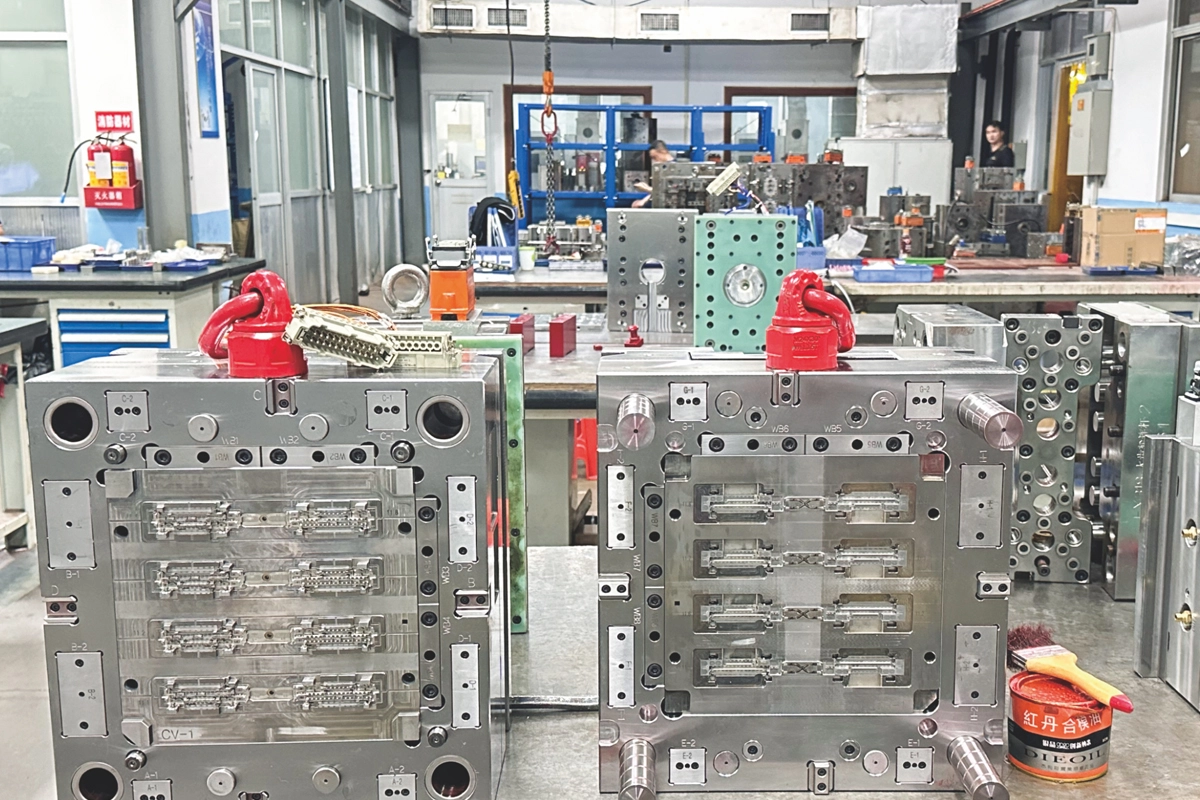

Capabilities:Dongguan City Fangling Precision Mould Co., Ltd. has grown into a leading manufacturer of precision plastic injection molds and spare parts, capable of achieving tolerances down to 1 micron. Their commitment to innovation extends beyond their equipment for precision molding, encompassing training programs that ensure their technicians are equipped to meet the evolving demands of industries like automotive and telecommunications. Whether you need standard designs or customized precision mould solutions, Dongguan City Fangling Precision Mould Co., Ltd. combines quality, precision, and affordability to be your top choice for high precision molding needs.

Website: https://www.fangling-precisionmold.com/

Location: Dongguan, Guangdong

Founded: 2001

Core Services: Injection mold manufacturing

Capabilities: ISO/TS 16949/2009 and GMP certified, offers molds for the automobile, electronics, and home appliances sectors, uses steel and aluminum for compatibility with polymers

Website: https://richfieldsplastics.com/

Location: Dongguan, Guangdong

Founded: 1996

Core Services: Mold design, injection molding, secondary processing, final assembly

Capabilities: Operates 145+ machines (90–1000 tons). Excels in high precision molding for automotive, medical, and electronics, including EDM sinking mold parts and wire cutting mold parts.

Website: www.hanking-mould.com

Location: China

Founded: Early 2000s

Core Services: Plastic mold tooling, production and assembly of plastic injection products

Capabilities: Custom molded plastic for 3C devices, consumer parts, medical products, smart home applications, smart bracelets, multi-functional precision metal structural parts, and molding parts for smart payment solutions

Website: https://baiwemolding.com/plastic-injection-molding/

Location: Shenzhen, Guangdong

Founded: 1990

Core Services: High-precision plastic molding, rubber manufacturing

Capabilities: 11,000-square-meter complex, ISO 9001:2015 certified, meets RoHS and REACH standards, serves clients like Cannon and Honey Well

Website: https://rilongprecisionmold.com/

Location: Shenzhen, Guangdong

Founded: 2008

Core Services: Precision injection molding, mold design, rapid prototyping

Capabilities: Runs 80–450-ton machines, producing 40–50 molds monthly. Specializes in mould spare parts and core and cavity for automotive, electronics, and OEM applications. Exports to North America and Europe.

Why They Stand Out: Focus on high-precision components and efficient mould trial processes, supported by advanced Swiss and Taiwanese machinery.

Website: https://ecomolding.com/

RiLong Precision Mold was founded in 1990 in Shenzhen, China. The company offers high-precision plastic molding services. The firm is based in an 11,000-square-meter complex that houses the mold-making and injection molding departments. During 2006, RiLong continuously increases its capacity by establishing a rubber manufacturing division in Dongguan. RiLong is certified to ISO 9001:2015 and meets RoHS and REACH standards. Some of its customers include Cannon and Honey Well which rely on the company for quality components.

Website: https://rilongprecisionmold.com/

Location: Taizhou, Zhejiang

Founded: 1978

Core Services: Mold design, injection molding, plastic part production

Capabilities: Produces 900 molds annually, specializing in core and cavity and mould spare parts for automotive, home appliances, and furniture. Uses advanced CNC and 3D printing for precision.

Website: www.immould.com

Location: Hong Kong (factories in China)

Founded: 1984

Core Services: Injection molding, mold design, multi-component molding

Capabilities: Operates 11 factories with 6–1000-ton machines, producing precision mold parts for automotive, medical, and electronics. Supports advanced techniques like gas-assisted molding and in-mold labeling.

Website: www.tontec.com

Cost-Effectiveness: Lower labor and production costs offer 30–50% savings compared to Western markets.

High Capacity: Large facilities with 24/7 operations and advanced machinery (e.g., CNC wire-cut EDM machines, CNC high-speed milling machines) support high-volume production.

Precision and Quality: Certifications like ISO 9001, ISO 13485, and IATF 16949 ensure compliance with global standards, critical for precision mold parts and mould spare parts.

Comprehensive Services: Many companies offer end-to-end solutions, from mold design to mould trial and assembly, streamlining production.

Verify Certifications: Ensure ISO 9001 or industry-specific certifications (e.g., ISO 13485 for medical, IATF 16949 for automotive).

Check Capabilities: Confirm expertise in core and cavity, EDM sinking mold parts, or wire cutting mold parts based on your needs.

Assess Export Experience: Look for companies with a track record of serving global clients for reliable communication and quality.

Evaluate Equipment: Advanced machinery like centerless grinder machines or punch grinder machines ensures precision and efficiency.