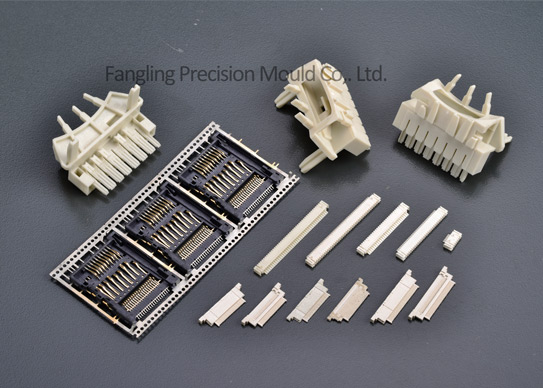

In the world of manufacturing, few processes are as versatile and efficient as injection molding. If you've ever wondered, "What is injection molding?" or "What is the injection molding process?", you're not alone. This technique powers the production of everything from smartphone cases to automotive parts. As a leading precision injection mold manufacturer founded in 2004, Dongguan City Fangling Precision Mould Co., Ltd. specializes in crafting molds with tolerances as low as 1 micron using advanced CNC machines and EDM technology. In this comprehensive guide, we'll break down the essentials, explore types, and show how it drives innovation—while highlighting how our expertise can elevate your next project. Ready to mold your ideas into reality? Let's dive in.

At its core, injection molding is a manufacturing method where molten plastic (or other materials) is injected into a precisely engineered mold cavity under high pressure. The material cools and solidifies, forming a part that matches the mold's shape. But what does injection molding do exactly? It enables mass production of complex, high-precision components with minimal waste, making it ideal for industries like electronics, medical devices, and consumer goods.

The injection molding process typically unfolds in four key stages:

Clamping: The mold halves are securely closed by a clamping unit to withstand injection pressure.

Injection: Plastic pellets are heated to a molten state (around 200-300°C) and injected into the mold at speeds up to 100 mm/s.

Cooling: The material cools inside the mold, usually taking 10-60 seconds, depending on part size and material.

Ejection: Pins or plates push the solidified part out, ready for the next cycle.

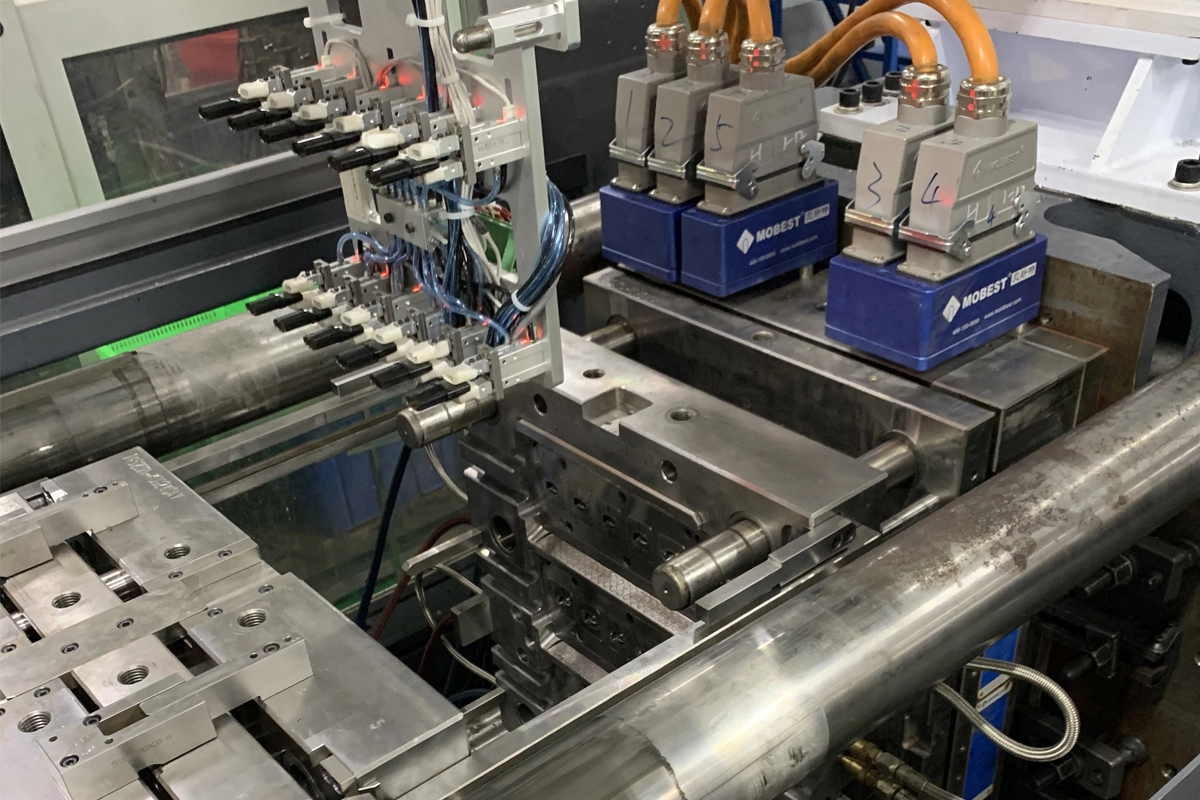

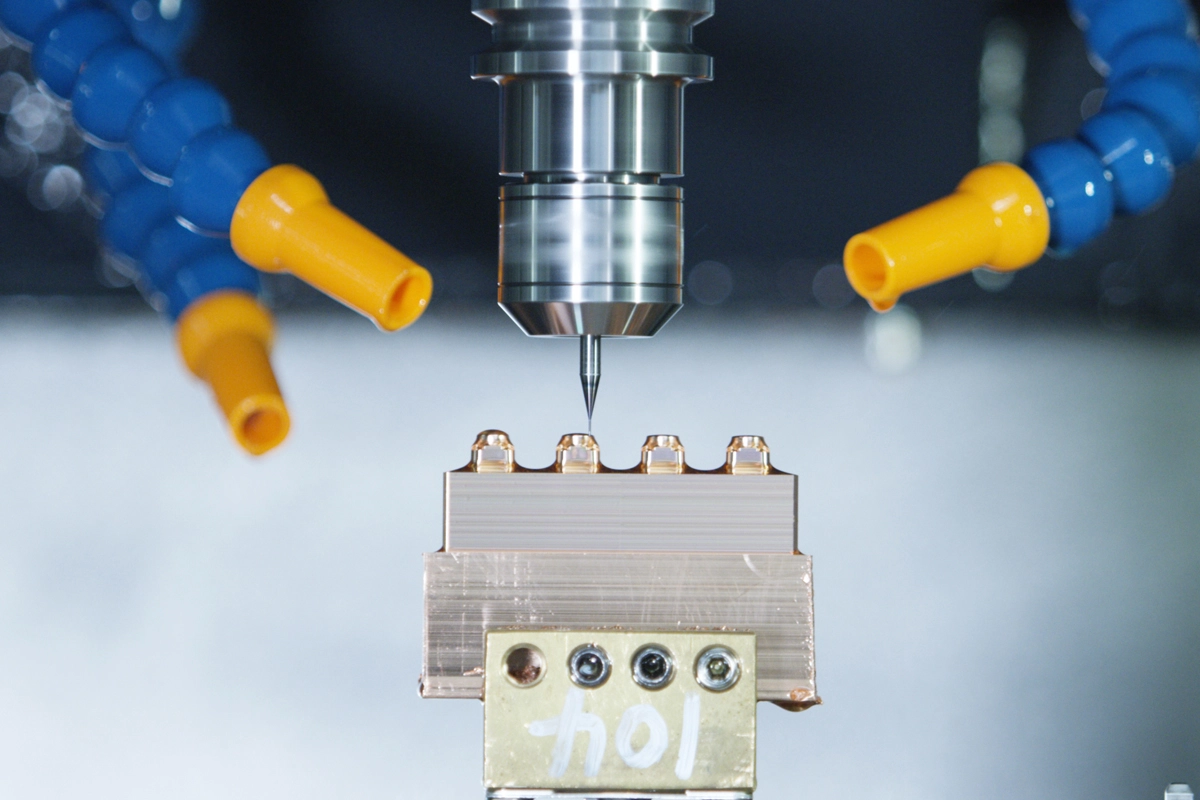

This cycle repeats in seconds for high-volume runs, producing thousands of identical parts. Searches for "what is the injection molding process" reflect its popularity, but precision is key— that's where Dongguan City Fangling Precision Mould Co., Ltd. shines. As a specialized precision moulding company, our ISO 9001:2008-certified facility uses 14 CNC electrode discharge machines (EDM) and 6 CNC wire-cut EDM machines to create molds that ensure 100% quality compliance. Our premium machining equipment for precision molding ensures that our high-precision products, such as mould spare parts, meet the highest standards of quality and performance. Curious about your custom needs? Contact us for a free consultation.

Why does this matter? Traditional methods like machining waste material, but injection molding recycles up to 95% of scraps, reducing costs and environmental impact. It's no wonder "what is plastic injection molding" garners 720 monthly searches—it's the backbone of modern plastics production.

Not all injection molding is created equal. With queries like "what are the types of injection molding" on the rise, understanding variations helps manufacturers choose the right fit. Here's a breakdown of the most common types, each optimized for specific applications:

The most widespread type, using heat-softenable plastics like ABS, polypropylene, or nylon. What plastics are used for injection molding? Thermoplastics dominate due to their recyclability and strength—think LEGO bricks or bottle caps. At Dongguan City Fangling Precision Mould Co., Ltd., we machine core cavity mold parts with our 4 CNC high-speed milling machines for tolerances under 1 micron, perfect for intricate designs.

Ever asked, "What is 2K injection molding?" ? This process injects two different materials or colors in sequence on the same machine, bonding them seamlessly. It's ideal for multi-material parts like soft-grip tool handles. Our advanced sinker EDM parts ensure flawless integration, minimizing defects.

What is insert molding? It embeds metal inserts (like threads or screws) into plastic during molding for enhanced durability. Overmolding adds a second layer for aesthetics or functionality. We produce threaded parts and jigs & fixtures using our 8 punch grinders, serving automotive and medical sectors.

For "what is metal injection molding", MIM mimics plastic injection but with fine metal powders. It crafts tiny, complex parts like gears or surgical tools. While we focus on plastic molds, our precision grinding (31 flat & profile machines) supports hybrid projects.

What is Micro Injection Molding: For parts under 1mm, like microfluidic devices.

What is Reaction Injection Molding (RIM): Mixes reactive resins for large, lightweight parts.

What is Compression Molding Used for: Heats and compresses material for thermosets.

Each type demands custom molds—our 4 hard turning machines excel here, delivering cylindrical and stamping mold parts with micron-level accuracy.

The beauty of injection molding lies in its versatility. Virtually anything plastic: from toys and packaging to aerospace components. Key applications include:

Consumer Goods: Phone cases, toys like our "Jumping Moon Mold" designs.

Automotive: Dashboards, bumpers—our cooler lake molds ensure efficient heat dissipation.

Medical: Syringes, implants with biocompatible plastics.

Electronics: Housings for circuits, leveraging our wild gold fish mold for fluid dynamics.

At Dongguan City Fangling Precision Mould Co., Ltd. , we go beyond molds to offer mould trial and final plastic moulded products, ensuring your prototype scales seamlessly. Our "Unforgettable Rainfall Mold" exemplifies intricate water-flow simulations for outdoor gear.

Hot tip: What is a hot runner in injection molding? Hot runners keep plastic molten in the mold, reducing waste by 30%. We integrate these in our precision molds for faster cycles.

A mold is only as good as its maker. What are injection molds made of? Typically hardened steel, aluminum, or beryllium copper for durability—up to 1 million cycles. Our state-of-the-art measurement equipment verifies every spec.

What are the types of injection molds? Two-plate, three-plate, or hot/cold runner varieties. We craft all, including stack molds for high output.

Quality is our mantra—100% customer satisfaction via ISO standards. With 4 centerless grinders and 1 profile grinder, we handle everything from EDM wire-cut parts to two-wheel grinding.

Since 2004, Dongguan City Fangling Precision Mould Co., Ltd. has been a trusted partner for medium-scale precision needs. Our comprehensive processes—from CNC milling to mold assembly—deliver unbeatable value. Whether it's "what is plastic molding" basics or advanced "scientific injection molding", we're here.

Ready to start? Our free quote process takes 24 hours. Inquire now and let's turn your vision into precision parts. What project are you molding next?