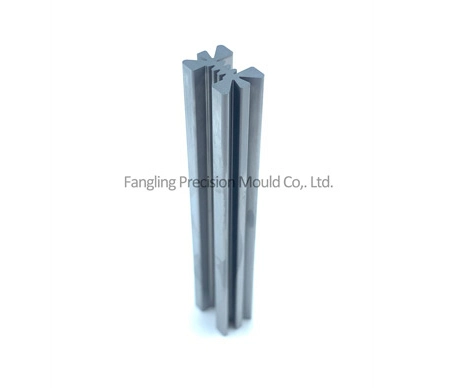

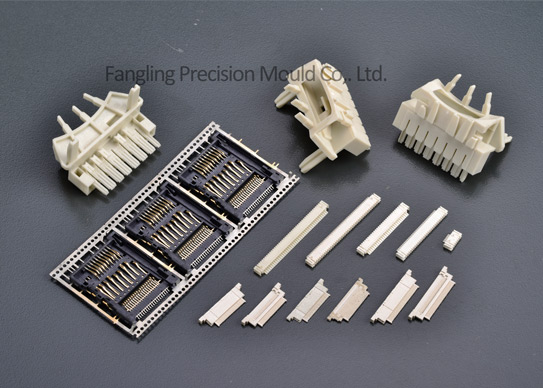

In the high-stakes world of precision manufacturing, where tolerances as tight as 1 micron define success, your injection moulding machines are the heartbeat of production. Founded in 2004, Dongguan City Fangling Precision Mould Co., Ltd. has built its reputation as a medium-sized enterprise specializing in high precision molding and mould spare parts—like cylinder parts, ejector pins, and fully customized components. With our highly skilled technicians, advanced machinery including 31 flat and profile grinding machines, 6 CNC wire-cut EDM machines, and 14 CNC EDM sinking machines, we understand the critical role maintenance plays in ensuring flawless output. Poorly maintained machines lead to defects, downtime, and costly repairs—issues that can derail even the most quality-centric operations like ours, which adhere strictly to ISO 9001:2008 standards.

This comprehensive guide dives deep into injection moulding machine maintenance, offering practical, educational insights to help you optimize performance, extend equipment life, and achieve 100% customer satisfaction. Whether you're running high-volume production of core cavity injection molding or custom molds like our Icy River or Wild Gold Fish designs, proactive maintenance is non-negotiable. Read on to learn actionable strategies, and if you're ready to elevate your setup with precision spare parts or expert mold assembly, contact Dongguan City Fangling Precision Mould Co., Ltd. today for a free consultation.

Injection moulding machines are complex beasts, blending hydraulic, electrical, and mechanical systems to inject molten plastic into molds with pinpoint accuracy. At Dongguan City Fangling Precision Mould Co., Ltd. , we've seen firsthand how a single overlooked maintenance task can cascade into major failures. For instance, neglecting hydraulic fluid checks can cause pressure inconsistencies, leading to uneven fills in precision molds— especially critical when producing injection molding cylindrical parts — and resulting in skyrocketing scrap rates.

The stakes are high: according to industry reports from the Plastics Industry Association, unplanned downtime costs manufacturers an average of $50,000 per hour. But the real pain point? Quality erosion. Our commitment to micron-level precision means every part—from EDM sinking mold parts to CNC high-speed milling components—must perform flawlessly. Regular maintenance ensures your machines deliver consistent results, reducing defects and aligning with standards like ISO 9001:2008.

Beyond cost savings, effective maintenance boosts efficiency. Well-maintained machines run cooler, use less energy, and produce higher yields. In our precision mold factory, where we handle everything from trial-run molding to final plastic products, we've integrated maintenance into our daily workflow, resulting in zero quality deviations over the past year. If your operation faces similar challenges, consider how upgrading to high-quality OEM milling parts and standard mold spare parts could transform your reliability.

Daily checks form the foundation of injection moulding machine maintenance—simple habits that prevent small issues from becoming big headaches. Think of it as a health checkup for your equipment; skipping it invites trouble.

Start with visual inspections. Before each shift, scan for leaks, unusual noises, or wear on critical components like nozzles, screws, and barrels. At Dongguan City Fangling Precision Mould Co., Ltd. , our technicians use state-of-the-art measurement tools to verify alignments, ensuring no deviations exceed 1 micron. Pro tip: Document findings in a logbook to spot patterns early.

Next, cleaning protocols are essential. Residue buildup from plastics can clog channels, affecting flow rates. Use non-abrasive cleaners on hoppers, screws, and molds—avoid harsh chemicals that could degrade seals. For molds like our Jumping Moon or Spring Forests designs, we recommend purging compounds during color changes to flush out contaminants without disassembly.

Don't overlook lubrication. Hydraulic systems thrive on clean, properly leveled oil. Check levels daily and top off with manufacturer-recommended fluids. In our setup with 4 CNC hard turning machines supporting mold production, we lubricate moving parts to minimize friction, extending life by up to 30%.

Finally, safety verifications. Test emergency stops, guards, and sensors. A malfunctioning sensor could halt production mid-cycle, costing thousands. By embedding these routines, Dongguan City Fangling Precision Mould Co., Ltd. maintains 100% uptime on our injection lines. Ready to implement? Our team offers customized maintenance checklists—reach out to get yours.

While daily tasks keep things humming, weekly maintenance uncovers issues that surface over time. This is where proactive diagnostics shine, especially for precision operations handling wire cutting mold parts or threaded mold parts.

Hydraulic system scrutiny tops the list. Drain and replace filters, inspect hoses for cracks, and test pressure gauges. Contaminated fluid can cause erratic clamping forces, ruining delicate cylindrical mold parts. At Dongguan City Fangling Precision Mould Co., Ltd. , with our 4 centerless grinder machines dedicated to such components, we perform fluid analysis weekly using spectrometry to detect wear metals early.

Electrical components demand attention too. Clean control panels, tighten connections, and calibrate thermocouples. Overheating wiring in heater bands is a common culprit for inconsistent melt temperatures—critical for our precision plastic injection molds. Use a multimeter to verify voltages; deviations signal impending failures.

For mechanical integrity, alignment and calibration are key. Run test cycles to check platen parallelism and ejector alignment. Our 8 punch grinder machines ensure ejector pins meet exact specs, but machine misalignment can shear them prematurely. Employ laser alignment tools for micron accuracy.

Vibration analysis rounds out weekly checks. Attach sensors to detect imbalances in the screw or pump, which could lead to premature wear. In our experience producing jigs and fixture parts, this has prevented 80% of potential breakdowns. These steps not only safeguard your investment but also enhance product quality, mirroring our 100% customer satisfaction rate.

Monthly maintenance is your deep clean and tune-up, addressing wear that accumulates over weeks. For manufacturers producing stamping plastic parts or standard mould parts, this level of care ensures scalability without surprises.

Full system flushes are non-negotiable. For hydraulics, circulate fresh oil through the system and replace all filters. In plastic lines, disassemble and purge barrels thoroughly—essential for multi-material runs like our Cooler Lake or Unforgettable Rainfall molds. Neglect this, and degraded polymers can contaminate batches.

Inspect clamping mechanisms closely. Lubricate tie bars, check for scoring on platens, and torque bolts to spec. Our 14 CNC EDM machines produce cavity inserts that demand uniform clamping; loose fittings cause flash or short shots.

Electrical overhauls include relay testing and insulation resistance checks. Faulty solenoids can misfire valves, disrupting cycles. Use thermal imaging cameras to spot hot spots in motors— we've caught motor winding issues at Dongguan City Fangling Precision Mould Co., Ltd. before they escalated.

Don't forget software and controls. Update firmware, calibrate PLCs, and run diagnostic scans. Modern machines integrate IoT for predictive maintenance; if yours doesn't, it's time for an upgrade.

At Dongguan City Fangling Precision Mould Co., Ltd. , monthly audits involve our entire quality team, aligning with ISO protocols. This rigorous approach has kept our mould trial error-free. If downtime is plaguing your shop, our precision spare parts—like custom ejector pins—can slot right in post-overhaul. Inquire now for tailored solutions.

Even seasoned operators fall into traps. One major pitfall? Inconsistent scheduling. Ad-hoc maintenance leads to oversights; combat this with digital calendars or CMMS software, alerting teams to tasks.

Another: Using subpar parts. Generic seals or filters fail faster under precision loads. At Dongguan City Fangling Precision Mould Co., Ltd. , our two-wheel grinding parts and grinding mold parts are engineered for longevity—insist on OEM-quality replacements, especially for EDM aluminum parts and OEM milling parts.

Overlooking environmental factors is sneaky. Dust or humidity accelerates corrosion; maintain cleanrooms and humidity controls, as we do for our fantastic Summer mold production.

Finally, skipping training. Technicians need ongoing education on evolving tech. Our skilled team undergoes annual refreshers, ensuring expertise in CNC high-speed milling mold parts.

By dodging these, you'll slash repair costs by 40-50%, per industry benchmarks. Dongguan City Fangling Precision Mould Co., Ltd. got your back with training resources—let's discuss.

Looking ahead, predictive maintenance is revolutionizing the field. AI-driven sensors forecast failures by analyzing data trends—imagine preempting a pump seizure before it halts your wild Gold Fish mold run.

Sustainability ties in too: Energy-efficient retrofits and biodegradable lubricants reduce your footprint while cutting costs. At Dongguan City Fangling Precision Mould Co., Ltd. , we're integrating these into our mold assembly processes for greener production.

Embracing this future means less reactive fixes and more innovation. Our final plastic moulded products benefit from such forward-thinking, delivering unmatched quality.

Injection moulding machine maintenance isn't just upkeep—it's a strategic edge. From daily visuals to monthly overhauls, these practices ensure your operations run like clockwork, producing flawless parts every time.

At Dongguan City Fangling Precision Mould Co., Ltd., we've honed this expertise since 2004, crafting everything from core and cavity mold parts to bespoke injection molds with micron precision. Our comprehensive machining—spanning 6 CNC wire-cut EDM machines to 4 hard turning machines—guarantees compatibility with your needs. Whether you need spare parts, mold assembly, or trial-run molding, we're here to drive your success.

Don't let maintenance mishaps hold you back. Contact us today for expert advice, custom quotes, or a complimentary maintenance audit. Let's precision-engineer your productivity together.