Mould assembly is a critical phase in injection molding, ensuring precision mould parts integrate seamlessly to produce high-quality components. From automotive dashboards to medical devices, effective mould assembly enhances production efficiency and product reliability. This article explores best practices, challenges, and innovations in mold assembly, providing insights to streamline your manufacturing workflow.

Mold assembly involves combining precision mold parts into a cohesive unit ready for injection molding. This process ensures proper alignment, functionality, and durability, directly impacting the quality of finished products. A well-executed mold assembly minimizes downtime and maximizes the lifespan of the mold, making it a cornerstone of efficient manufacturing.

Achieving optimal mold assembly requires a structured approach:

Accurate alignment of precision mould parts is fundamental to mould assembly. Misalignment can lead to defects like flash or uneven filling. Using jigs and fixtures, manufacturers ensure each part fits perfectly, supporting consistent production outcomes.

The plastic molding resin used influences mould assembly compatibility. Resins like PP, with high elasticity, or POM, with low friction, must be paired with precision mold parts that withstand their properties. Material testing ensures seamless integration and performance.

Post-assembly testing verifies the functionality of the mould assembly. Pressure tests and trial runs identify issues like leaks or misalignment, allowing adjustments to precision mould parts before full production. This step ensures reliability and reduces waste.

Mold assembly presents several hurdles that require strategic solutions:

Intricate precision mold parts can complicate mold assembly. Detailed designs demand skilled labor and precise tools, increasing the risk of errors if not managed properly.

Over time, mould assembly components experience wear, especially under high-pressure molding conditions. Regular maintenance and spare precision mould parts availability are essential to avoid production delays.

Adapting mould assembly for large-scale production requires consistent quality across multiple units. Standardized processes and robust training help maintain efficiency as demand grows.

Advancements are transforming mold assembly practices:

Automation streamlines mould assembly by reducing manual effort and errors. Robotic systems ensure precise placement of precision mold parts, boosting productivity and consistency.

Simulation software predicts mould assembly performance, identifying potential issues before production. This tool optimizes the integration of precision mould parts, enhancing efficiency and reducing costs.

Modular mould assembly allows for quick reconfiguration of precision mold parts. This flexibility supports rapid adaptation to new product designs, improving responsiveness to market changes.

Optimizing mold assembly involves mastering alignment, material compatibility, and innovative techniques. Addressing challenges and adopting new technologies ensures a robust process that delivers high-quality outcomes.

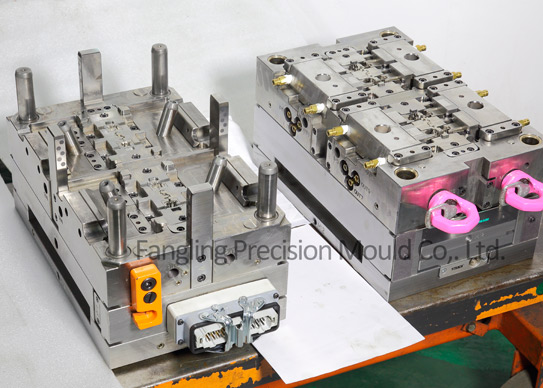

For superior mould assembly and precision mould parts, Dongguan City Fangling Precision Mould Co., Ltd. stands out. Since 2004, we have specialized in injection molding, leveraging advanced equipment and ISO 9001:2008 certification to achieve 1-micron tolerances. Our technician training and comprehensive support streamline mold assembly for clients in Japan, Germany, and beyond. Contact Fangling today for a free quote and enhance your production with our expertise.