Selecting the right plastic molding resin is a critical step in ensuring the success of your injection molding project. Whether you’re producing components for automotive, medical, or consumer goods, the choice of plastic molding resin impacts durability, cost, and performance. This article explores key factors to consider when choosing plastic molding resin, helping you make informed decisions to optimize your manufacturing process and achieve high-quality results.

Plastic molding resin serves as the foundation of injection molding, transforming raw materials into functional parts. Derived from refined crude oil through a process called cracking, these resins are polymers formed from hydrocarbon chains. The versatility of plastic molding resin lies in its ability to be tailored with additives, making it suitable for diverse applications. Understanding its composition—ranging from monomers to enhanced polymers—helps identify the best fit for your project.

Choosing the ideal plastic molding resin requires evaluating several criteria to match your project’s needs:

The mechanical requirements of plastic molding resin determine its suitability. Hardness, measured on the Durometer scale, indicates resistance to indentation, while flexibility measures bending without breaking—nylon may be soft but brittle, whereas ABS offers hardness with elasticity. Tensile strength, the ability to withstand loads, varies across resins, with options like HDPE excelling in high-stress environments. Consider your product’s purpose and environmental exposure when selecting.

Plastic molding resin must resist chemical interactions, such as those from cleaning agents or process reagents. Resins like PEEK offer exceptional chemical resistance, making them ideal for industrial applications, while PP handles food-grade contacts well. Review manufacturer data on chemical performance to ensure your chosen resin maintains integrity under specific conditions.

Different plastic molding resin types respond uniquely to temperature, UV light, and humidity. PC and PMMA resist high heat and provide transparency, suitable for optical lenses, while LDPE excels in moisture resistance but struggles with heat. Assess your product’s operating environment—extreme cold, heat, or outdoor exposure—to select a resin that performs reliably.

The density of plastic molding resin affects its weight, influencing manufacturing and end-use applications. Lightweight options like PP are perfect for packaging, while heavier PVC suits structural components. Balancing weight with strength ensures cost-effective production and practical design.

Plastic molding resin costs vary based on production complexity and market availability. Common resins like ABS or PP are affordable due to widespread use, while specialty resins like PEEK command higher prices. Prioritize material properties over cost initially, then seek cost-effective suppliers to optimize your budget.

Exploring specific plastic molding resin options highlights their unique benefits:

Known for toughness and malleability, ABS is widely used for automotive parts, toys, and electronics. Its ability to adhere to other materials makes it versatile for coating applications, ensuring durable precision mold parts.

With high elasticity and heat resistance, PP suits food containers, automotive components, and insulation. Its low friction properties enhance performance in moving parts, a key consideration for mould assembly.

PC’s impact resistance and transparency make it ideal for bulletproof glass, phone screens, and medical lenses. Its heat tolerance supports demanding environments, aligning with high-quality precision mold parts.

PEEK’s chemical and heat resistance suits aerospace and medical devices, such as compressor plates. Its strength ensures reliability in critical mold assembly applications.

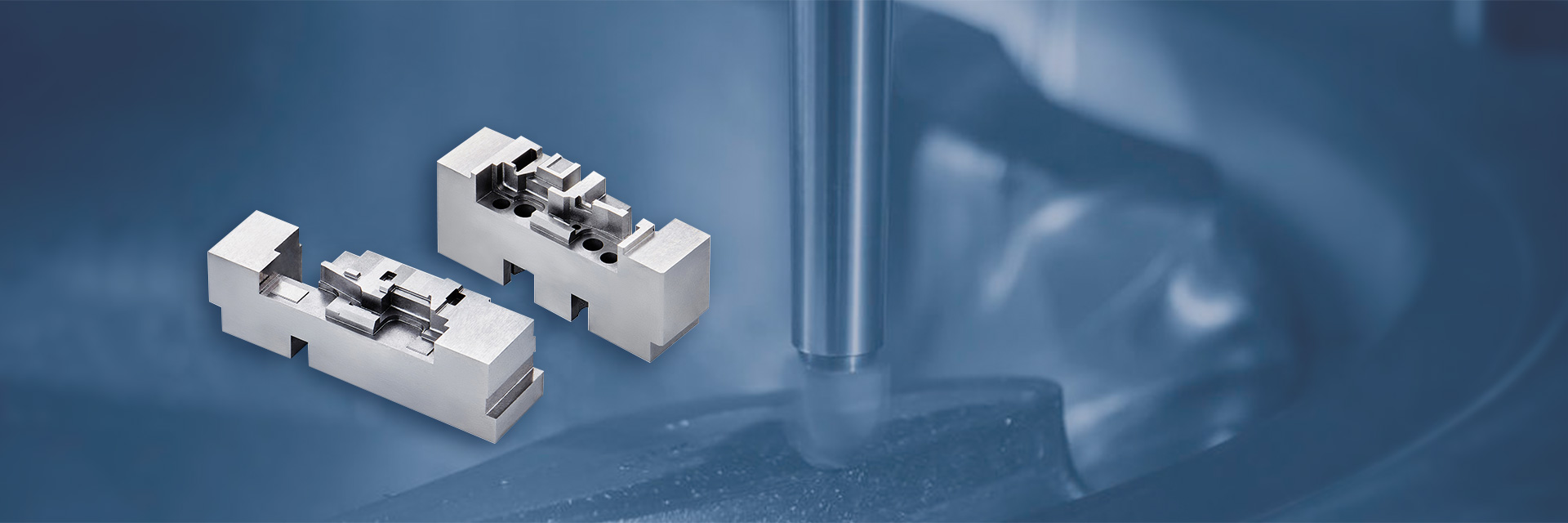

POM’s low friction and dimensional stability are perfect for gears and fixtures. Its wear resistance enhances the longevity of precision mold parts in mechanical systems.

Selecting the appropriate plastic molding resin involves balancing mechanical, chemical, and environmental factors with cost and availability. This decision directly influences the quality of precision mold parts and the efficiency of mold assembly. Conduct thorough research and consult with material experts to align your choice with project goals.

For projects requiring the perfect plastic molding resin, Dongguan City Fangling Precision Mould Co., Ltd. offers unmatched expertise. Established in 2004, we specialize in injection molding, delivering high-quality precision mold parts and mold assembly with 1-micron tolerances. Our advanced equipment and ISO 9001:2008 certification ensure optimal resin selection and processing. Contact Fangling today for a free consultation and elevate your project with tailored plastic molding resin solutions.