Precision mold parts are the backbone of high-quality injection molding, driving performance across industries like automotive, medical, and electronics. Achieving excellence in precision mould parts manufacturing requires advanced technology, rigorous processes, and a deep understanding of material interactions. This article delves into the techniques and considerations that ensure precision mold parts meet exacting standards, enhancing product reliability and efficiency.

Precision mold parts are defined by their ability to maintain tolerances as low as 1 micron, critical for components like medical syringes or electronic housings. This precision ensures consistency, reduces waste, and supports complex designs. Manufacturers rely on precision mould parts to deliver products that perform flawlessly under demanding conditions, making manufacturing expertise essential.

Producing top-tier precision mould parts involves several key techniques:

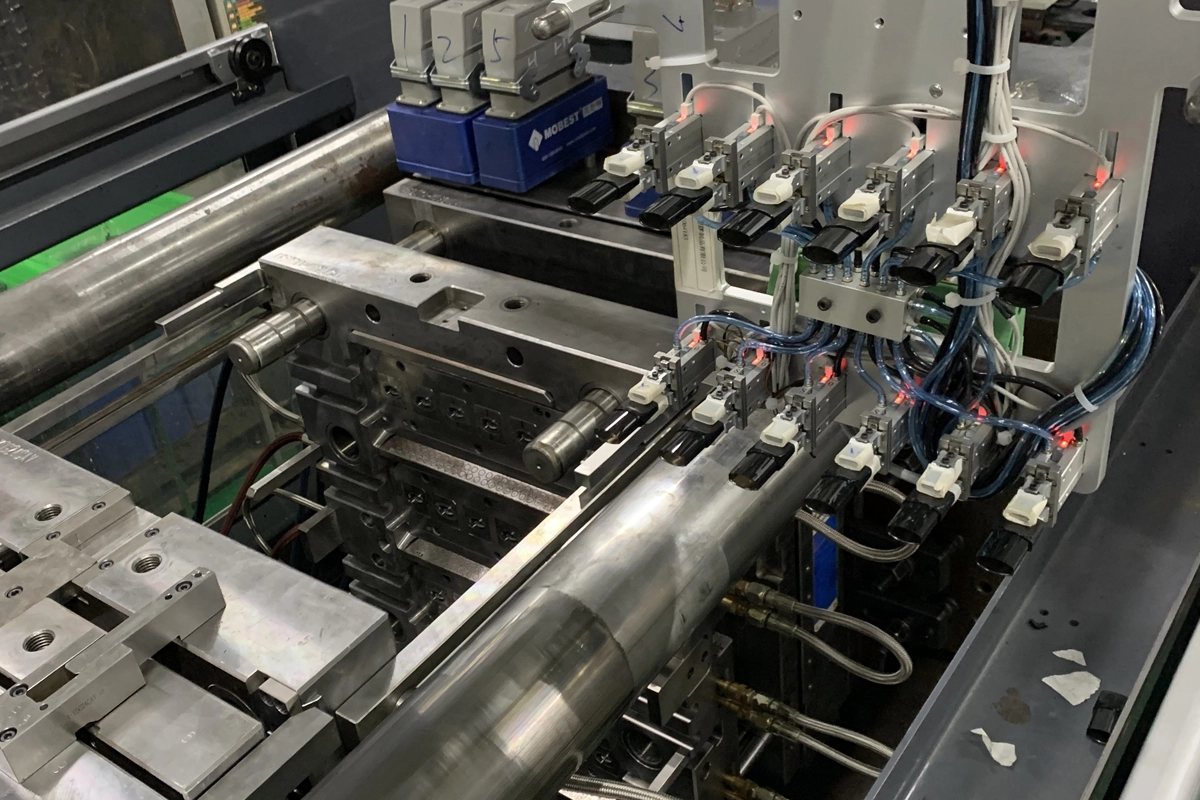

High-precision machining, using CNC high-speed milling and wire-cut EDMs, is vital for creating precision mold parts. These technologies allow for intricate geometries and tight tolerances, ensuring components like connectors or gears meet design specifications. Regular maintenance of equipment enhances accuracy and longevity.

The choice of plastic molding resin significantly affects precision mould parts. Resins like POM, with low moisture absorption, or PC, with high impact resistance, must be processed with precision to avoid defects like warping. Proper temperature and pressure control during molding ensure dimensional accuracy.

Stringent quality control is non-negotiable for precision mould parts. Using tools like NIKON or TRIMOS for dimensional checks, manufacturers verify every part against standards like ISO 9001. This step prevents defects and ensures precision mould parts perform as intended in mold assembly.

Manufacturing precision mold parts presents unique challenges that require careful management:

Achieving and sustaining 1-micron tolerances demands advanced equipment and skilled operators. Variations in temperature or material properties can compromise precision, necessitating real-time monitoring and adjustments.

Precision mould parts undergo significant stress during production. Selecting durable plastic molding resin and implementing regular maintenance prevent wear, extending mold life and maintaining quality.

Transitioning from prototyping to mass production of precision mold parts requires consistent processes. Manufacturers must adapt machinery and workflows to maintain precision across volumes, a task that benefits from experienced oversight.

Recent advancements enhance the manufacturing of precision mold parts:

Automation, combined with AI, optimizes machining and quality control, reducing human error. This technology ensures precision mould parts are produced with consistent accuracy, even in high-volume runs.

Mold flow analysis predicts material behavior, minimizing defects in precision mold parts. This tool allows designers to refine mould assembly processes, improving efficiency and reducing costs.

Using eco-friendly plastic molding resin options supports sustainable precision mould parts production. Innovations in recyclable materials align with industry trends while maintaining performance standards.

Mastering precision mold parts manufacturing requires a blend of technology, material science, and quality assurance. By addressing challenges and leveraging innovations, manufacturers can produce components that meet the highest standards.

For superior precision mold parts, Fangling delivers cutting-edge solutions. Founded in 2004, Dongguan City Fangling Precision Mould Co., Ltd. specialize in injection molding with advanced CNC milling and wire-cut EDMs, achieving 1-micron tolerances. Our ISO 9001:2008 certification and skilled technicians ensure top-quality precision mold parts for diverse industries. Contact Fangling today for a free quote and transform your manufacturing with our expertise.